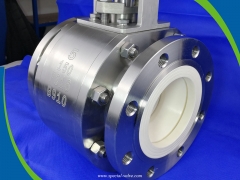

Three-piece forged body

Forged body avoids cast defect of cast body;

O-port & V-port ball

O-port ball mainly used as shut off function;

V-port ball mainly used as control function;

V-port ball can cut off fiber to avoid blocking;

Ball in material of

Ceramic ZrO2

Ball requires material with high flexural strength;

Ceramic ZrO2 has higher flexural strength than Ceramic

Al2O3;

Seat in material of

Ceramic Al2O3

Seat requires material with high pressure resistance.

Ceramic Al2O3 has higher pressure resistance than Ceramic

ZrO2.

Body fully lined with

Ceramic Al2O3

Body fully lined with ceramic Al2O3 is protected from wear

and corrosion.

Excellent Anti-corrosion

performance

The 99% Al2O3 and ZrO2 ceramics are inert to almost all

organic and inorganic chemicals except hydrofluoric acid.

The Silicon carbide ceramic is resistant to hydrofluoric acid.

Strong stability in strong acid, strong alkali and strong

corrosive slurry avoids pollution to the service.

Excellent Anti-abrasion

performance

The 99% Al2O3 ceramic with hardness of HRA88 and the ZrO2

ceramic with hardness of HRA85 are many times harder than stainless steel and cemented

carbide.

The extreme hardness makes the ceramic with high wear

resistance against friction in pneumatic conveying of powder and abrasive

slurry with hard solid content in industries of steel, metallurgy,

petrochemical, mining, power plant, paper, pulp and polysilicon etc.

Excellent seal

performance

Through precise grinding, the ceramic ball closes tightly to

the ceramic seat to achieve zero leakage (class VI).

There is no any space between the ball and seat to avoid blocking

problem.

Small operate torque

The characteristic of high hardness and extreme low surface

roughness reduces the friction coefficient of sealing face and the operate

torque of valve.

Equipped with ISO 5211 mounted pad

Pneumatic actuator and electric actuator can be connected

with the ball valve through ISO 5211 mounted pad.

Product range:

Size: DN15~DN300 1/2’’ ~12’’

Pressure rating: PN16—PN100 150lbs—600lbs

End connection: Flanged RF RTJ

Body materials: A105 F304 F316 lined with Al2O3 ceramic

Seat materials: Al2O3 ceramic

Ball materials: ZrO2 ceramic

Technical standards:

Design: ASME B16.34

Face to Face: ASME B16.10

Flanged ends: ANSI B16.5 EN1092-1

Test & Inspection: API598

Products

Products

Industries

Industries

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

Ceramic Butterfly Valve For Abrasive Slurry

Ceramic Butterfly Valve For Abrasive Slurry

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder