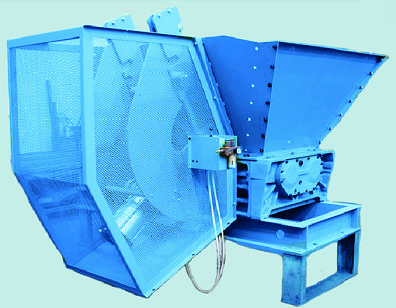

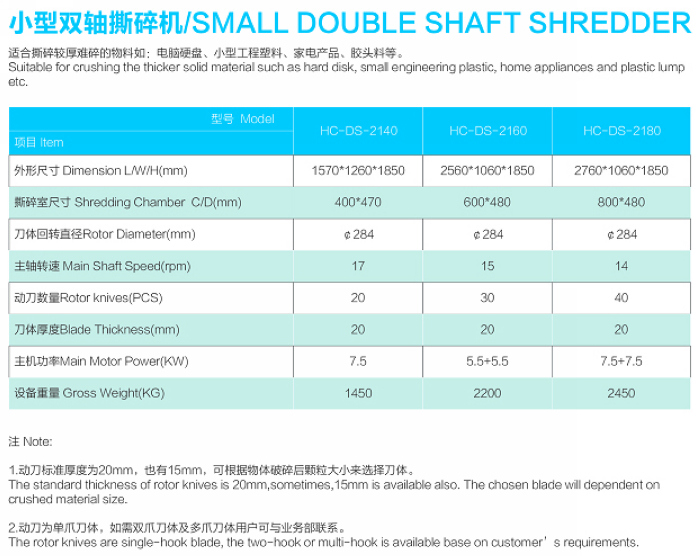

The HC double shaft secondary

shredder is specially

design for fine shredding the solid waste into size of 8 mm to 80mm with design

output of 0.3 T/h to 100T/H.

Applications:

Suitable for but

not limited to

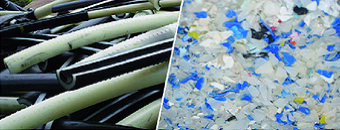

Plastic film, plastic pellets, plastic drum, pipe Aluminium, steel, car, cooper wire & cable

Wood pallets, railroad tires, wood board Tires, rubber products, leather products

c

Medical waste, perfusion tube, injection tube Various slaughtered poultries: pigs, chicken etc.

Textile, carpet, old clothes, shoes, mattress Hard disc, TV, fridge, circuit board, Monitor

Others:

Municipal solid waste, industrial waste, biomass, kitchen food waste, coconut, agriculture straw etc.

Main components:

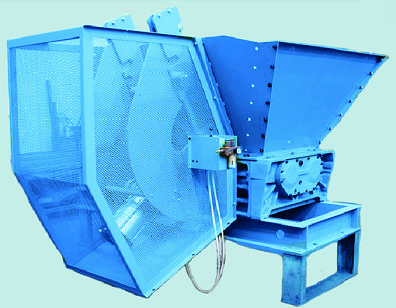

Rotating

screen:

The

rotating screen can be installed on the double shaft secondary shredder to

control the output size. The rotating trommel screen around the shredder body

makes the shredded oversize particle back into the shredder hopper to be

shredded again.

Hydraulic feeder:

When shredding large hollow waste, the shredder can

be equipped with hydraulic ram to push the materials to the cutters for

shredding to increase the shredding efficiency.

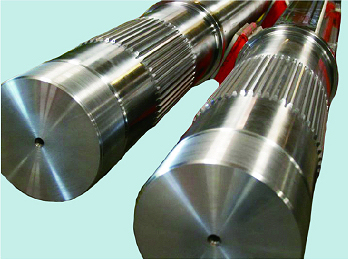

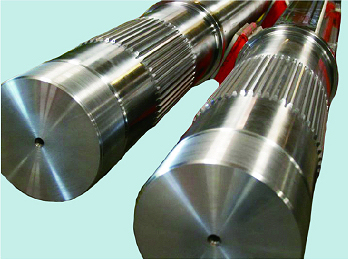

Main shaft:

The reducer and

the cutters are connected with the main shaft through Germany standard spline

with large transmission torque. The parts in the main shaft are not relative

sliding. The total contact area with many teeth is able to bear heavy load with

high positioning accuracy and even contacting pressure.

Double shaft cutters:

Products

Products

Industries

Industries

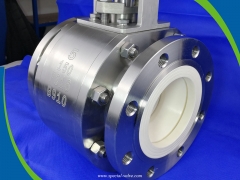

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

Ceramic Butterfly Valve For Abrasive Slurry

Ceramic Butterfly Valve For Abrasive Slurry

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder