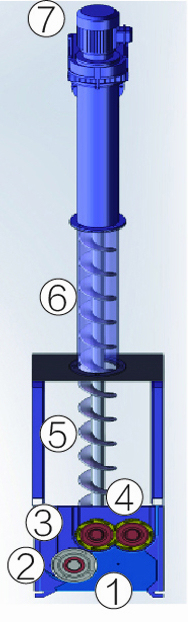

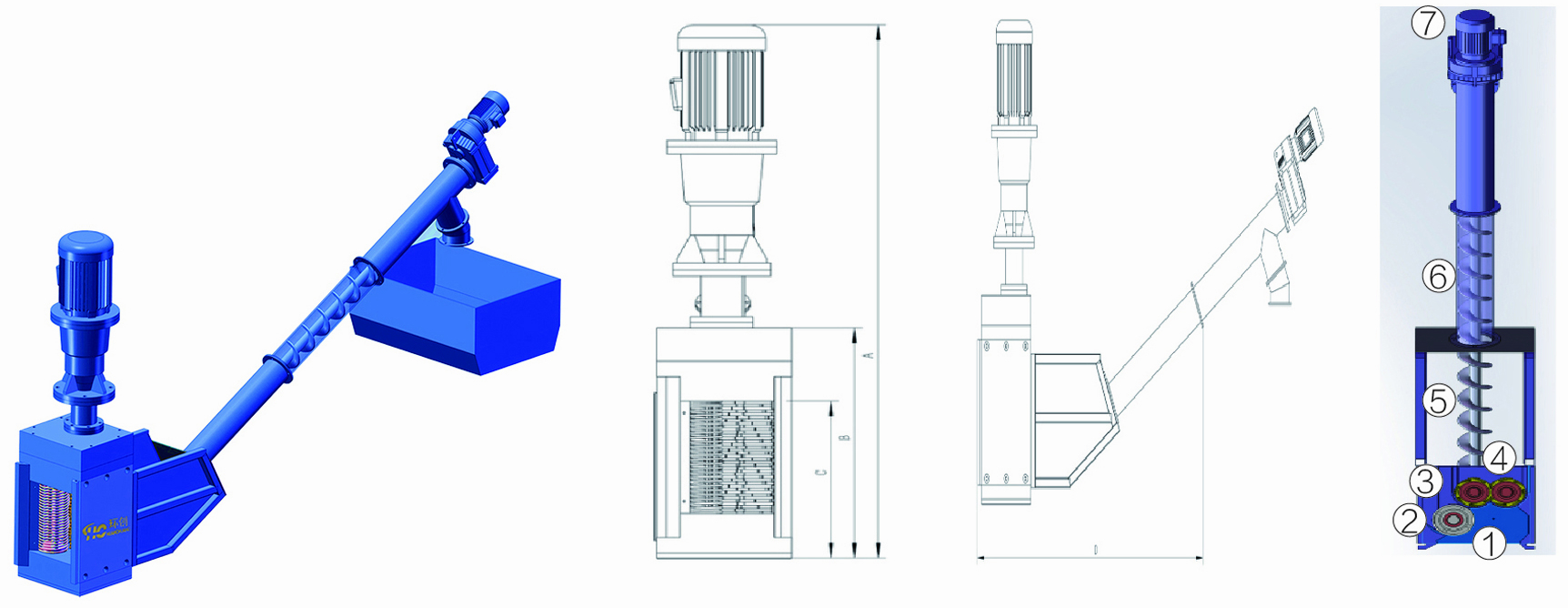

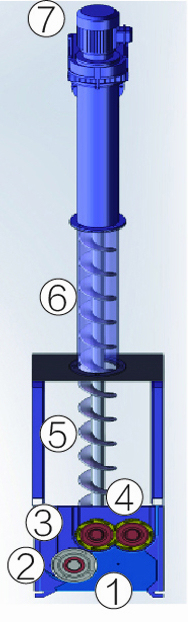

Working Principle:

1. Solid wastes contained in wastewater enter the HC spiral conveyor channel sludge grinder through open channel.

2. Solid wastes are captured and directed by the rotating screen drum into the cutting area.

3. Wastewater and small size solid wastes pass through the rotating screen drum.

4. Double shaft blades shred the solid wastes by rotating in opposite direction.

5. Solid wastes are reduced to 6 mm-12mm tiny particles and guided into inclined shaftless spiral conveyor.

6. After washing, separating with organic and dewatering, the clean odorless small solid particles are discharged.

7. The small solid particles fall into the container or bag.

Main benefits:

- Perfect combination for shredding solid wastes in high flow sewage and dewatering;

- Organics flow back to channel through the conveyor groove holes;

- Before discharge, the solid particles have been washing, lifting and dewatering;

- Spraying washing makes the solid particles more clean and odorless;

- Solid particles after washing and dewatering are more suitable for landfill.

Products

Products

Industries

Industries

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

Ceramic Butterfly Valve For Abrasive Slurry

Ceramic Butterfly Valve For Abrasive Slurry

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder