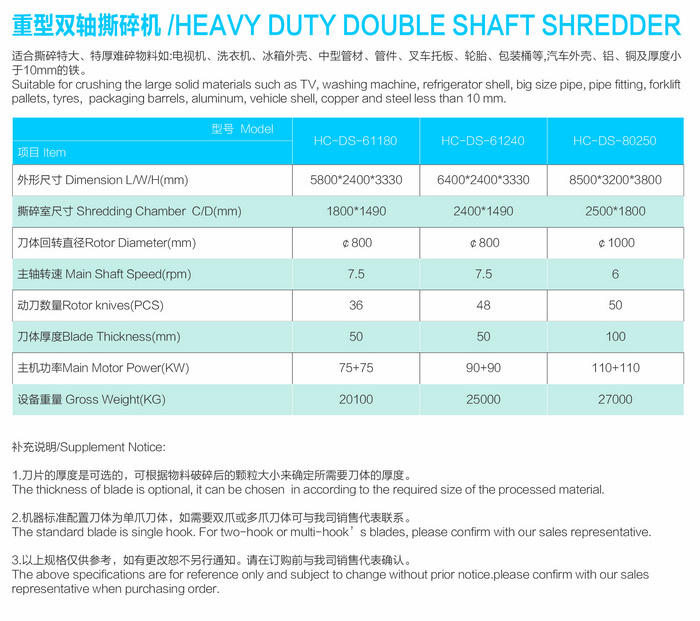

The HC Bulky waste double

shaft pre-shredder is specially design to pre-shred the bulky waste into size of 80mm to

250mm with design output of 10T/h to 100T/H.

Applications:

Suitable but not limited to

MSW Bulky Waste Pre-shredding Wood Pre-shredding

Car Shell Metal Pre-shredding WEEE Pre-shredding

Tire Pre-shredding C & D Waste Pre-shredding

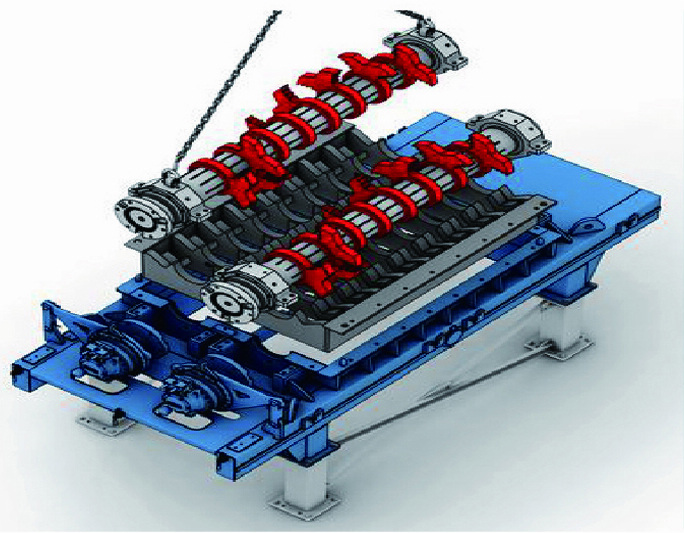

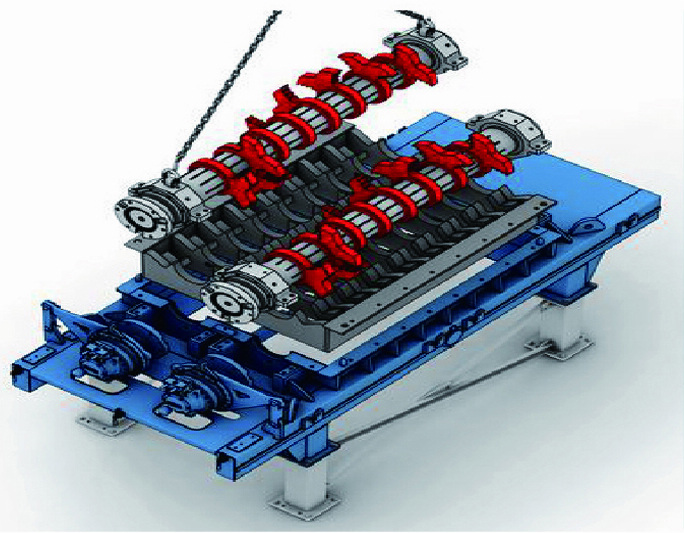

Main Components:

Hydraulic Drive:

The hydraulic drive replaces the motor drive to increase the torque for bulky waste and control the speed to achieve high torque, low speed and low noise. The hydraulic drive also ensure the stability of shredding and avoid mechanical damage of shredder.

Bearing Seat:

Bearing Seat:

Engineering strengthened design and split two-piece structure achieve convenient maintenance. The dust-proof clapboard prevents the liquid or debris from damaging the bearing seat so that service life of the bearing seat can be prolonged.

Double Shaft Blades:

The double shaft blades of HC MSW double shaft primary shredder are in material of heat treated HRADOX550 with hardness of HRC 52-55.The replaceable and interchangeable blades are convenient for overlaying repair and it can prolong the working life of blades and reduce customer’s running cost.

Various blades configurations to suit different applications:

PLC Control System:

Start, rotate reversely and stop automatically and remote controllable;

Motor protection when jamming, overloading, overheating and short circuit;

Electronic components are from international famous brand of Siemens, ABB, and Schneider;

Frequency is adjustable to adjust the rotating speed of blades according to the real production capacity to save energy.

Products

Products

Industries

Industries

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

Ceramic Butterfly Valve For Abrasive Slurry

Ceramic Butterfly Valve For Abrasive Slurry

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Bearing Seat:

Bearing Seat: