- Abrasion Resistant Valves

- Corrosion Resistant Valves

- Extreme Temperature Valves

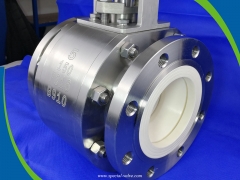

- Ball Valves

- Control Valves

- Gate, Globe & Check Valves

- Plug Valves & Butterfly Valves

- Knife gate valve&Slab gate valve

- API 6D Pipeline Valves

- API 6A Wellhead Valves

- Wear Protection Solutions

- Solid Shredding Solutions

- Auxiliary Equipments

Products

Products

- Power

- Chemical

- Oil & Gas

- Mining & Metallurgy

- Marine

- Paper & Pulp

- Municipal Utilities

- Food & Pharmaceutical

Industries

Industries

-

New Products

-

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

-

150LBS 5'' F316 Body Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

-

Ceramic Butterfly Valve For Abrasive Slurry

Ceramic Butterfly Valve For Abrasive Slurry

-

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

-

What's News?

- Ebonite lined Y type globe valves exported to Brazil

- Abrasion resistant Ceramic Double Disc Gate Valve for coal-fired power station

- DN600/DN1000 Hydraulic slow closing butterfly valve in hydro power station

- DN125 Wear resistant ceramic double disc gate valves for thermal power plants

- High temperature high pressure safety valves passed 3rd party inspection