Wedge with function of

self-cleaning

When close, the wedge will scrape the residue on the sealing

face to ensure excellent seal performance.

The wedge can cut off the solid and fiber in the medium to

avoid the problem of jam fault during operation.

Excellent Anti-abrasion performance

Seat and Disc lined in

material of ceramic with extreme hardness are wear resistant against friction

in pneumatic conveying of powder and abrasive slurry with hard solid content in

industries of steel, metallurgy, petrochemical, mining, power, cement, paper,

pulp and polysilicon etc.

Excellent Anti-corrosion performance

The ceramics are inert to

almost all organic and inorganic chemicals.

Strong stability in

strong corrosive slurry avoids pollution to the service.

Much longer service life

Service life of seat and

disc lined with ceramic is much longer than that of conventional metal steel.

Product range:

Size: DN15~DN600 1/2’’ ~24’’

Pressure rating: PN10/150lbs

End connection: Flanged RF Wafer Lug

Body materials: WCB/CF8

Disc materials: 304/316+ceramic

Seat materials: ceramic

Technical standards:

Design: MSS SP-81

Face to Face: ASME B16.10

Flanged ends: ANSI B16.5 EN1092-1

Test & Inspection: MSS SP-81

Products

Products

Industries

Industries

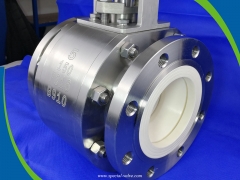

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

Ceramic Butterfly Valve For Abrasive Slurry

Ceramic Butterfly Valve For Abrasive Slurry

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder