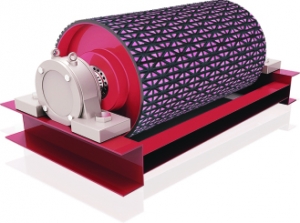

The drum is used as the main power part of the conveyor belt. The belt conveyor is usually transported with a mixture of coal or ore. The equipment has a long working time, which requires the drum to have high wear resistance, high tensile strength and tear resistance. If it is outside operations, the drum is also susceptible to weather (such as rust, sludge). The traditional rubber roller

easy to wear, slip off, damage conveyor belt, resulting in belt conveyor load drop, frequent equipment replacement.

YFL new ceramic pulley lagging was made by bump ceramic and special rubber vulcanized together. And then install the lining on the drum with glue to replace the traditional rubber lining. It can enhance the belt and roller friction coefficient; improve the drum service life. At the same time, each column of ceramic trench, easy to drain mud, ensure normal operation in harsh environments, and play the role of maintenance and cleaning the belt.

Wear resistance: the use of high wear resistance of ceramics can prolong the service life of 8-10 times than the traditional rubber.

Do not slip, do not run away: ceramic bump design to ensure adequate friction coefficient, the groove is designed to facilitate

drainage, mud, to ensure that the belt does not slip in the run, do not run away.

Easy installation, can be on-site installation: Use cold bond technology, import adhesives, on-site installation, reducing the intensity of the workers disassembly downtime, improve work efficiency.

Products

Products

Industries

Industries

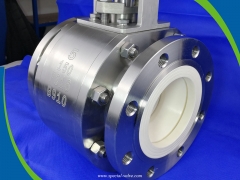

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 3'' F316L Pneumatic Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

150LBS 5'' F316 Body Ceramic Lined Ball Valves

Ceramic Butterfly Valve For Abrasive Slurry

Ceramic Butterfly Valve For Abrasive Slurry

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder

Pneumatic Ceramic Knife Gate Valve for SiO2 Powder